[2024] Whetstone stand

I am Okudaira, the owner of "Japanese Kitchen Knife TOKU''.

We want to sell knives made in our hometown of Sakai, Osaka, so we purchase and sell knives made in Sakai from a knife manufacturer in Sakai.

We don't just sell knives, we visit a number of blacksmiths and bladesmiths in Sakai to help our customers understand knives, experience the actual work, and hear from the craftsmen. I'm here. In addition to Sakai, we also visit Seki in Gifu, Tsubame-Sanjo in Niigata, Tanegashima in Kagoshima and Katsushika in Tokyo, in an effort to deepen our understanding of the characteristics and commitment of each.

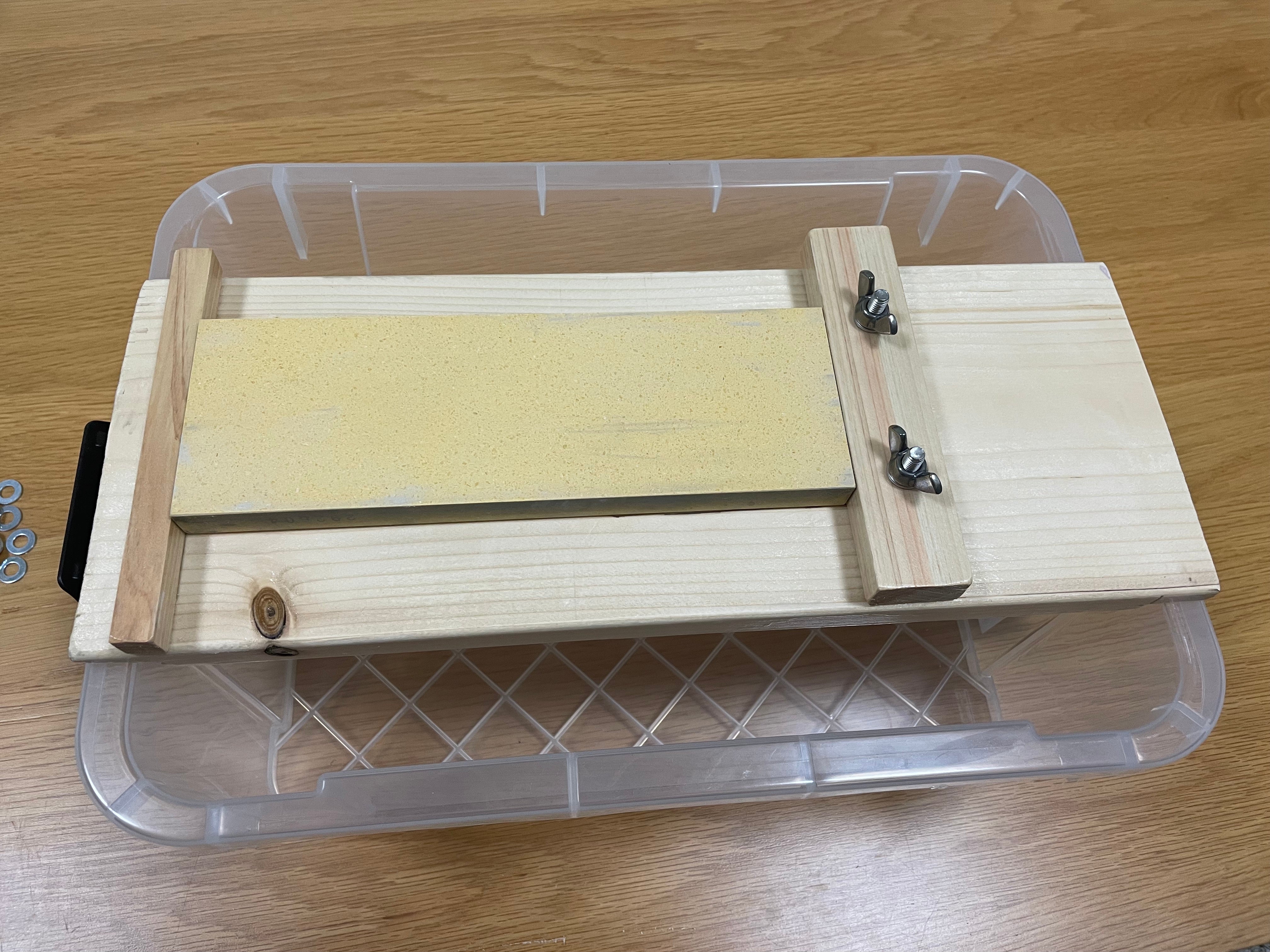

Whetstone Stand

Do you know there is such a thing as a whetstone stand?

It is used to hold the whetstone in place when sharpening knives.

Some whetstones for sale come with a wooden stand.

If you are using a thick whetstone to sharpen a knife, you can place the whetstone on a wet towel and you will not need a whetstone stand.

However, when sharpening with a thin whetstone, you will need to place the whetstone on some kind of stand.

Commercially available whetstone stands are made of stainless steel and can be fixed to fit the size of the whetstone, and each whetstone manufacturer also sells whetstone stands tailored to their own products.

There are also people who make their own whetstone holders.

I once saw someone create a whetstone holder using wood purchased from a hardware store to match their kitchen sink at home, and upload the video of how they made it to YouTube .

I also decided to make a whetstone stand in preparation for the knife sharpening workshop I am holding.

Since the knife sharpening training course will be held in a regular conference room, participants will be sharpening on a plastic case. For this reason, we needed to create a whetstone stand that would fit the plastic case.

I would like to write about the whetstone stand I made this time. I hope it will be helpful.

First, I chose a plastic case (with a lid) that wasn't too large to store whetstones and other necessities.

Next, I chose the wood for the base.

I wanted something as thick as possible, but after much consideration I decided to buy wood that was about 2cm thick.

You will also need to purchase some wood to hold the whetstone in place.

You will also need bolts, washers, two sets of wing nuts, varnish and a brush for applying the varnish.

The processing process begins with cutting a piece of wood to serve as the base to fit the plastic case.

Not only do you need to adjust the length, but you also need to cut both ends so that they don't move and fit into the plastic case.

Drill a hole to move the bolt according to the length of the whetstone you will be using. This is a process of drilling a hole and cutting it out with a saw. When drilling holes, if you drill the hole together with the wood to hold it in place, it will be easier to align the hole position because the hole will be drilled in the same position as the wood that will be the base.

Once you've done this, check to see if the bolt moves smoothly.

Once you've done that, apply a layer of varnish to protect it. If necessary, sand it down to prevent any thorns from cutting you.

There are many knife-related products on the market, such as the whetstone holders we have introduced here, but many of them are not well known, and even if they are available, they may not suit your needs.

In that case, DIY is probably the only option.

Let's go to a knife store!

If you don't understand it until you see it, go to a knife store and try holding a knife. However, most stores do not allow you to try cutting the knife, so you cannot check the sharpness before purchasing.

"Japanese Kitchen Knife TOKU'' does not have a store, but we set up stalls at events, so please feel free to stop by if we have one in your area.If there is no knife specialty store nearby, it is a good idea to purchase from an online knife specialty store.

"Japanese Kitchen Knife TOKU'' has posted a video showing the actual cutting process, so please use it as reference.

Sakaitoku Knife - YouTube

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.