[2024] Factory Open Day

I am Okudaira, the owner of "Japanese Kitchen Knife TOKU''.

We want to sell knives made in our hometown of Sakai, Osaka, so we purchase and sell knives made in Sakai from a knife manufacturer in Sakai.

We don't just sell knives, we visit a number of blacksmiths and bladesmiths in Sakai to help our customers understand knives, experience the actual work, and hear from the craftsmen. I'm here. In addition to Sakai, we also visit Seki in Gifu, Tsubame-Sanjo in Niigata, Tanegashima in Kagoshima and Katsushika in Tokyo, in an effort to deepen our understanding of the characteristics and commitment of each.

Factory Open Day

This time, I would like to talk about the Factory Open Day that I attended, which is held annually in Seki City, Gifu Prefecture.

As you may know, Seki City in Gifu Prefecture is one of Japan's leading knife production areas.

We also do business with a knife manufacturer in Seki City.

In addition to knife manufacturers, a wide variety of factories in Seki City are participating in the Factory Tour Day, including casting companies, contact lens manufacturers, and railway companies.

The main reason for my visit to Seki City, Gifu Prefecture on Factory Open Day this time was to tour the factory with which we do business.

Now, let me tell you about what happened on the factory tour of a knife manufacturer that we do business with.

First, we had a company explanation in the showroom. We heard about the year the company was founded and the pocket knives they made when they first started. Nowadays, they manufacture a wide variety of kitchen utensils, with a focus on knives.

After the explanation at the showroom, we will have a tour of the factory.

The production of stainless steel knives begins with carving a stainless steel plate into the shape of the knife.

Once shaped into a knife, the steel is hardened through a process called quenching.

Next, the thickness of the blade is thinned by machine. At this stage, the blade is not yet attached.

After this, the blades of the knives are sharpened by hand, one by one.

After the handle is attached with glue, excess glue is removed and the handle is polished with a sander, with several people taking turns to complete the process until it is smooth and shiny.

In the case of Damascus knives, the Damascus pattern is beautifully brought out by blowing fine glass onto the knife using a process called shot blasting. I had the opportunity to try out this shot blasting process. Apparently the amount and strength of the blowing affects how the pattern appears.

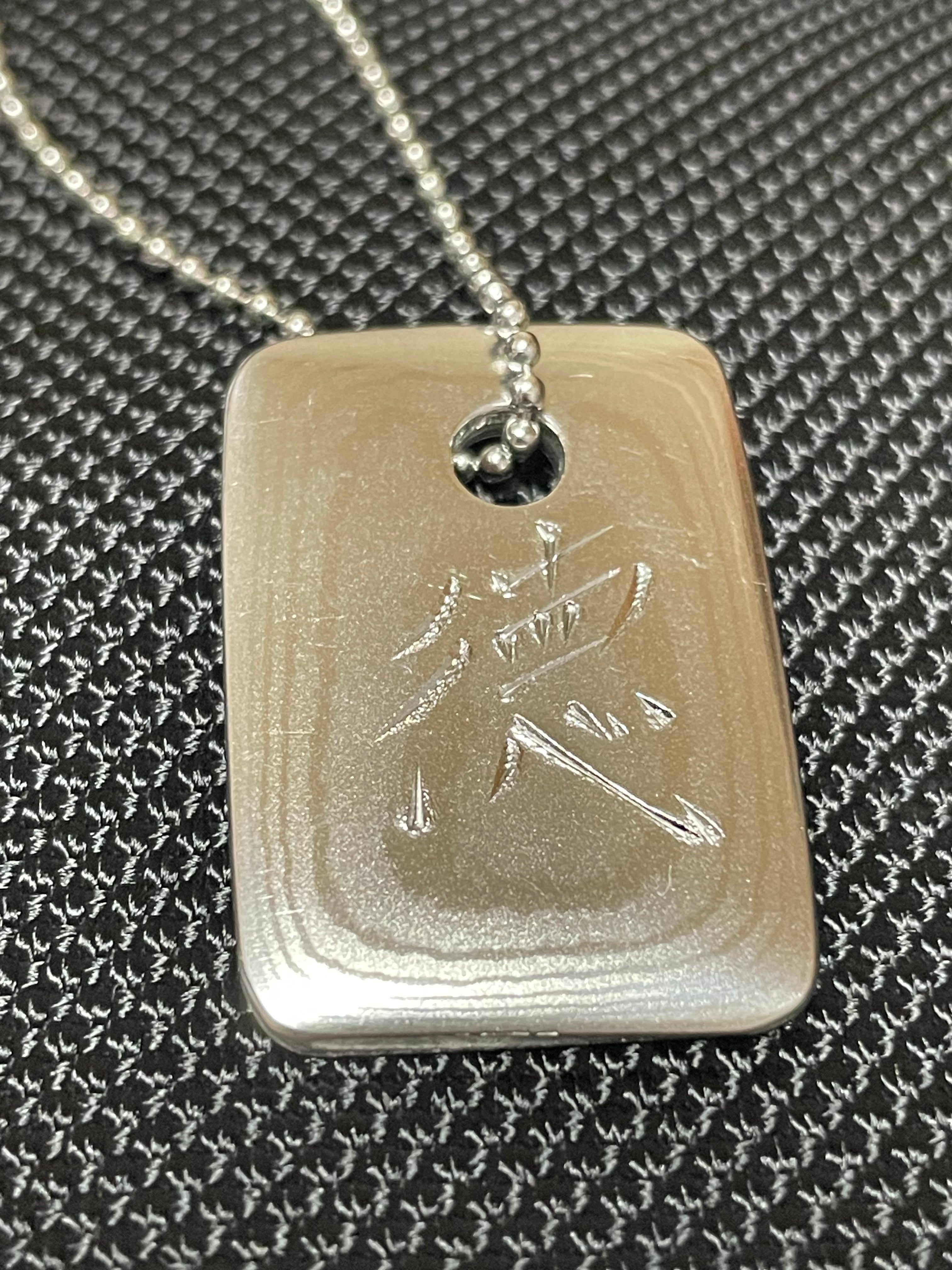

The final process for making a knife is inscribing. This is the process of putting a brand or product logo on the knife. There are two ways to do this: engraving with a laser or cutting the name with a chisel. Personally, I think cutting the name with a chisel is more appealing.

You might imagine that stainless steel knives can be mass-produced, but they are not all made automatically. Rather, people set each knife into the machine, check it, and then use the machine to perform the work. Although the process is mechanized, it is still the work of human craftsmen.

I got the sense that the craftsmen working there took pride in their work.

On this factory tour, we felt that we wanted to continue to convey the passion of these craftsmen to customers who purchase our products and customers who come to have their knives sharpened.

Let's go to a knife store!

If you don't understand it until you see it, go to a knife store and try holding a knife. However, most stores do not allow you to try cutting the knife, so you cannot check the sharpness before purchasing.

"Japanese Kitchen Knife TOKU'' does not have a store, but we set up stalls at events, so please feel free to stop by if we have one in your area.If there is no knife specialty store nearby, it is a good idea to purchase from an online knife specialty store.

"Japanese Kitchen Knife TOKU'' has posted a video showing the actual cutting process, so please use it as reference.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.